|

*valid for optional execution

https://www.trens.sk/sites/default/files/01_katalog_aj_small_9.pdf

https://www.trens.sk/sites/default/files/tech_list_sbl300_bez_27.pdf

Description

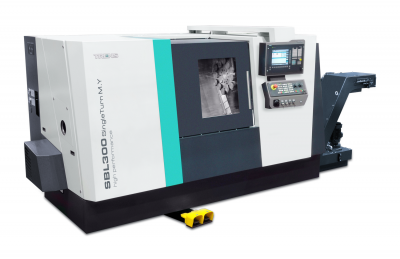

Machine designed for medium to large-series production for machining simple as well as complex shape workpieces. This machine signifi cantly contributes to increased productivity while considerably decreases investment costs.

Main characteristic features:

- Modular concept of the machine allows confi guration tailored to the customer´s individual requirements.

- Execution with electrospindles

- 12 position turret with VDI 25 couplings with live tools and Y-axis

- Remote diagnostics and data management

- Wide range of executions and accessories – hydraulic clamping with chucks or collets, bar feeders, tool probes, parts catchers, automatic door opening, work area vapour exhaust

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

Characteristic features

Productive turning centers of a rigid construction with slant bed designed for high precision and productive machining in challenging conditions of multi-shift operation.

- Variable building kit based on monolithic slant bed of cast iron – high rigidity and accuracy of the machine

- Quality components from renowned producers – long lifetime and long reliability while preserving repeatable accuracy of the machine

- Production of strategic components in own premises with continuous checking and accuracy evaluation at 3D measuring devices

- X-axis measuring by linear scale as a standard – increased machining accuracy

- Grease lubrication – lowering the environmental impact

- No-attendance automated mode with feeders and part catchers – lowering production costs

Main advantages

- High precision and productive machining of simple as well as complex shape workpieces

- Steady cutting process with high repeatable accuracy of machining

- Remote diagnostics and data management

- Modular concept of the machine allows configuration tailored to the technological needs of production

- Turret with VDI couplings with live tool drive and Y- axis

- Wide scope of executions and accessories – clamping devices, bar feeders, part catchers, tool probes, automatic door opening, vapour exhaust system

- Newest technologies in the field of drives bring savings in electric energy

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese