| Max swing diameter | 750 mm | |

| Max turning diameter | 500 mm | |

| Max bar diameter | 107 mm | |

| Max diameter of bars with spindle reduction sleeve or with spindle prolongation | 97 mm | |

| Max weight of workpiece in centers | 2500 kg | |

| Max weight of overhung workpiece | 250 kg |

https://www.trens.sk/sites/default/files/01_katalog_aj_small_63.pdf

https://www.trens.sk/sites/default/files/tech_list_sbl700_bez_4.pdf

Description

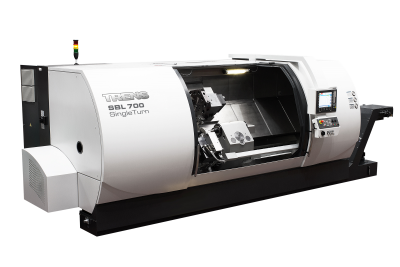

Top representative of SBL range turning centers is designed for medium to large series production for demanding machining of large-dimensions workpieces of complex geometrical shapes.

It is suitable for technological workshops focusing on large dimensions flange and shaft production in engineering where precision, quality and high production efficiency plays crucial role.

Main characteristic features:

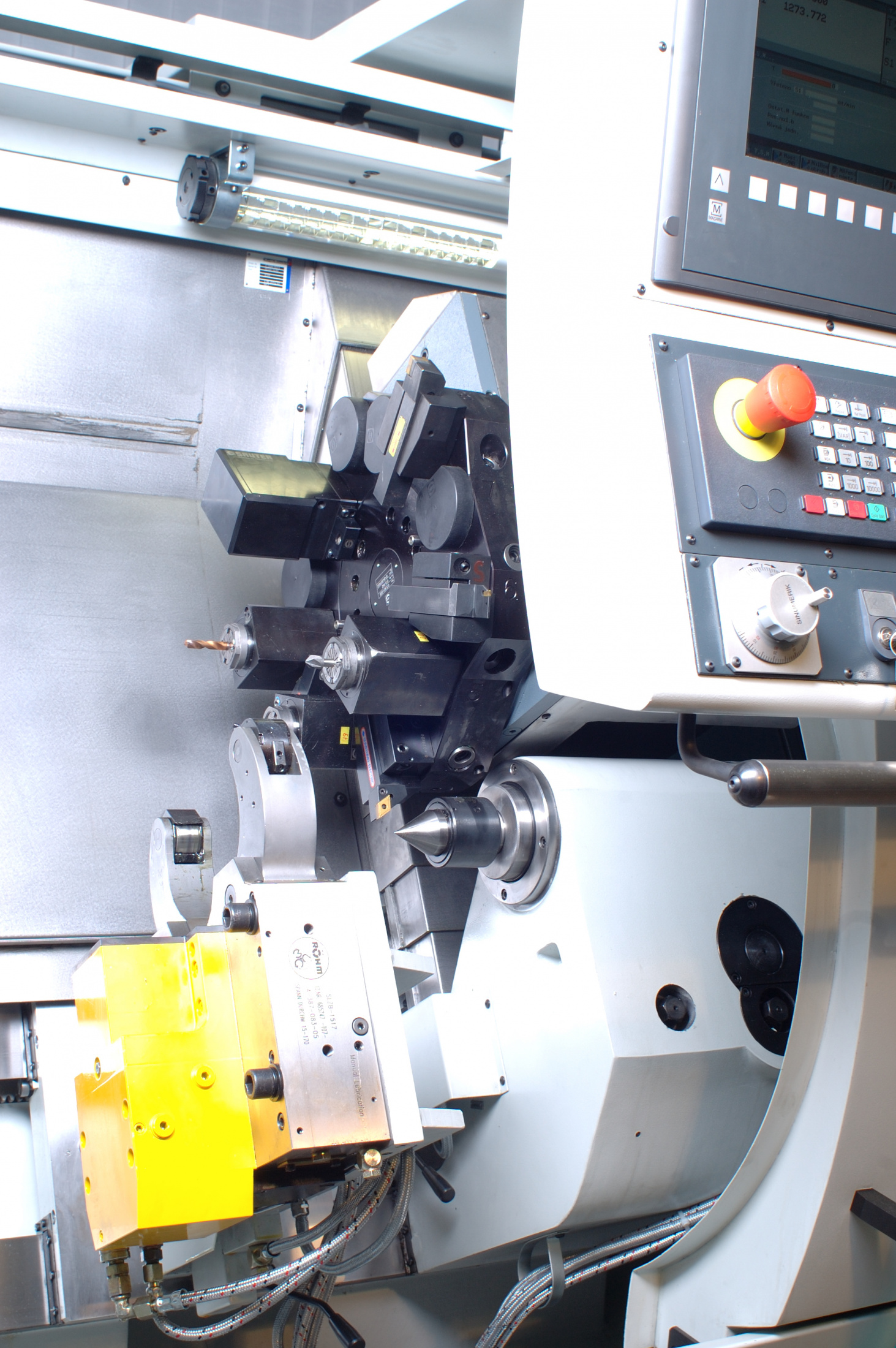

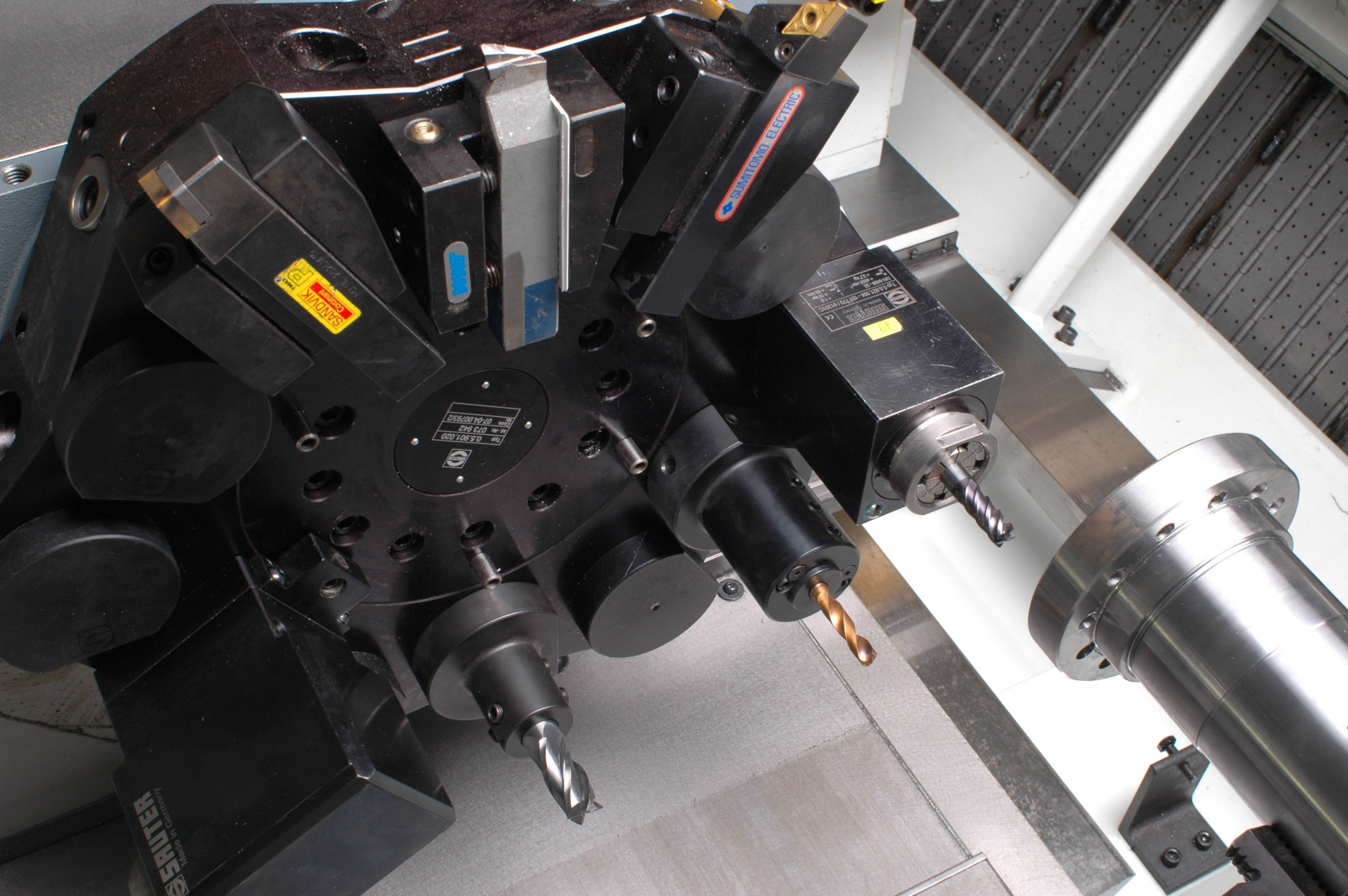

- 12-position turret VDI 50 without live tool positions

- Remote diagnostics and data management

- Main spindle motor output 37kW (S1)

- Wide range of executions and accessories – hydraulic clamping with chucks or collets, bar feeders, tool probes, automatic door opening, oil mist filtration from work area

- Covers with reinforced zones – high level of operator´s safety

| Carriages and drives | ||

| X-axis (VDI 50) | ||

| Operating feed | mm.min -1 | 1÷10000 |

| Rapid traverse of cross-slide | mm.min -1 | 16000 |

| Operating stroke | mm | 420 |

| Z-axis | ||

| Operating feed of longitudinal slide | mm.min -1 | 1÷10000 |

| Rapid traverse of longitudinal slide | mm.min -1 | 20000 |

| Operating stroke | mm | 2170 |

| Operating stroke with radial turret* | mm | |

| Tool post systems | ||

| 12-position axial turret | ||

| Number of positions | 12 | |

| Tool shank diameter (according to DIN 69880) | mm | 50 |

| Max. tool cross-section | mm | 32x32 |

Characteristic features

Productive turning centers of a rigid construction with slant bed designed for high precision and productive machining in challenging conditions of multi-shift operation.

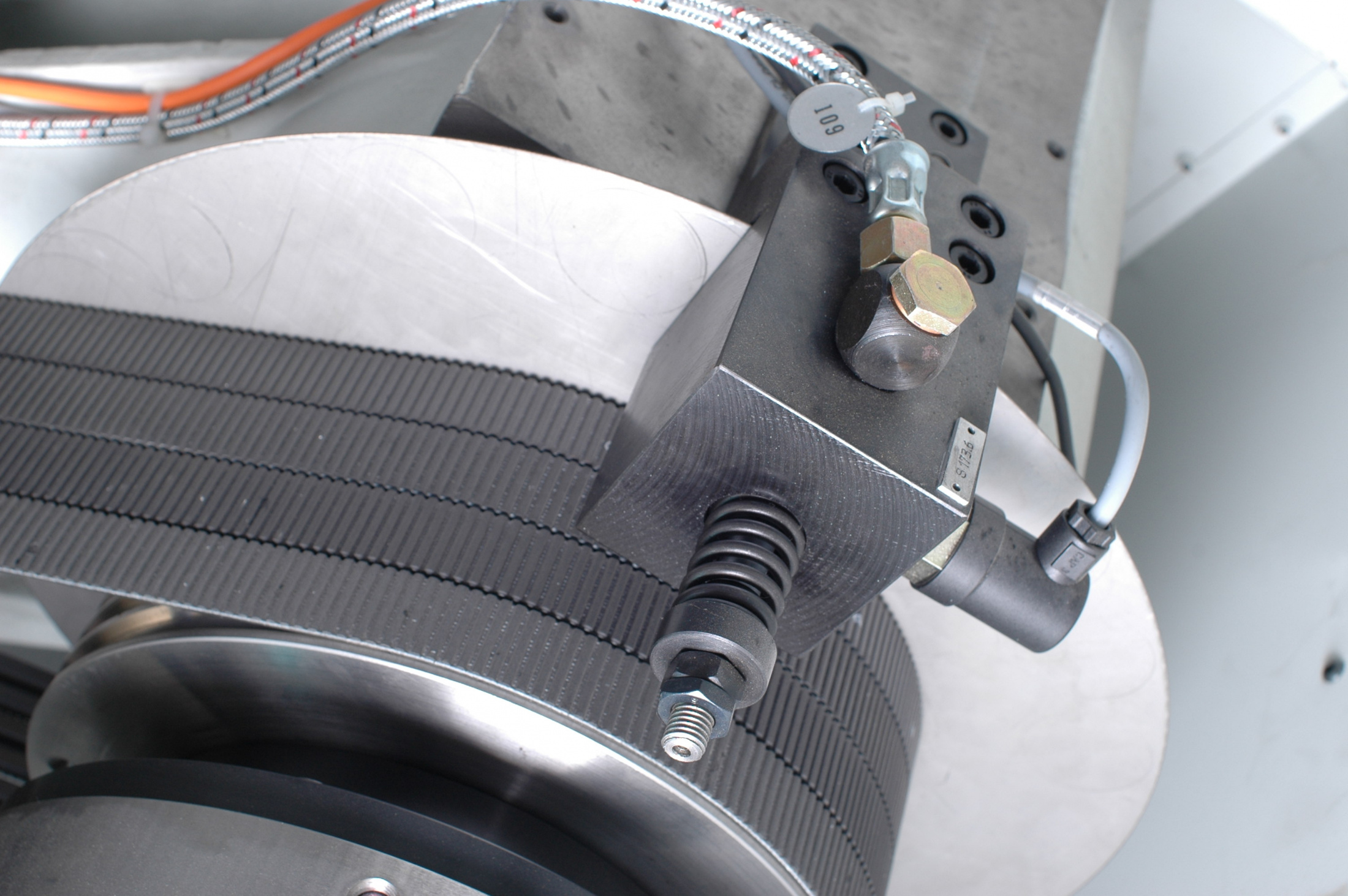

- Variable building kit based on monolithic slant bed of cast iron – high rigidity and accuracy of the machine

- Quality components from renowned producers – long lifetime and long reliability while preserving repeatable accuracy of the machine

- Production of strategic components in own premises with continuous checking and accuracy evaluation at 3D measuring devices

- X-axis measuring by linear scale as a standard – increased machining accuracy

- Grease lubrication – lowering the environmental impact

- No-attendance automated mode with feeders and part catchers – lowering production costs

Main advantages

- High precision and productive machining of simple as well as complex shape workpieces

- Steady cutting process with high repeatable accuracy of machining

- Remote diagnostics and data management

- Modular concept of the machine allows configuration tailored to the technological needs of production

- Variety of turrets with VDI couplings without live tool drive

- Wide scope of executions and accessories – clamping devices, bar feeders, part catchers, tool probes, automatic door opening, vapour exhaust system

- Newest technologies in the field of drives bring savings in electric energy

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese