| Max swing diameter | 800 mm | |

| Max swing diameter over cross slide | 515 mm | |

| Height of centers above bed | 394 mm | |

| Max bar diameter inside spindle | 130 mm | |

| Max weight of workpiece in centers; at speed up to 100 min -1 | 3500 kg | |

| Max weight of overhung workpiece; at speed up to 100 min -1 | 250 kg |

Description

SE820 Numeric Basic is a machine from category CNC universal center lathe designed for turning large rotational workpieces. It allows turning outer and inner cylindrical, conical and complex shapes and all kinds of threads as well.

They allow the machining of complex shapes from bars, forgings, and split material. Wide variability in specific turning operations for gas, oil, and water industries.

Main characteristic features:

- Ideal machine for a user switching from universal center lathe to CNC controlled machine

- Easy and comfortable control

- Long lifetime with focus on keeping high machining accuracy

- Headstock with 2-speed gearbox -the possibility of big diameter workpiece turning

- Automatic gear shifting during the working cycle

- Bearings with lifetime grease filling – low operating costs

- Direct spindle position measurement - high accuracy

- Annealed machine components for internal stress removal – high accuracy and stability throughout the lifetime of the machine

- Covers with reinforced zones – high level of operator´s safety

- Wide selection of optional executions and accessories – hydraulic clamping, hydraulic tailstock control, executions with increased distances between centers, a wide range of steadies and faceplates

| Manual tool post systems | ||

| Quick change tool post | MultiSuisse D1 | |

| Max. tool cross-section | mm | 40x40 |

| Manual modular tool post systems* | ||

| Quick change modular tool post | Parat RD 4* | |

| Max. tool cross-section | mm | 50x50* |

Characteristic features

These machines combine the advantages of conventional and CNC lathes. The machine works as a conventional lathe, in manual mode, is controlled by the handwheels. If required, the operation mode can be shifted to the full CNC control. Technological operations of machining can be programmed by simply filling in the pre-defined cycles or eventually by standard programming.

Machines are therefore suitable for piece and small-series production of simple as well as complex shapes of the workpieces from metal and plastic. The geometric accuracy of the machines fulfills norms ISO 1708 and ISO 230-1.

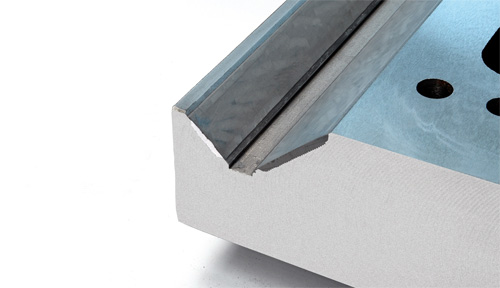

- Apron guideways with a layer of friction substance – reaching positional accuracy even at the minimal feed

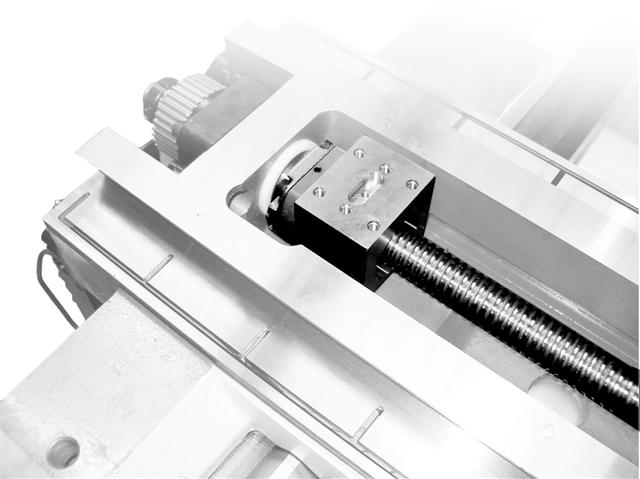

- Preloaded ground ball screws – high dimensional accuracy of workpieces

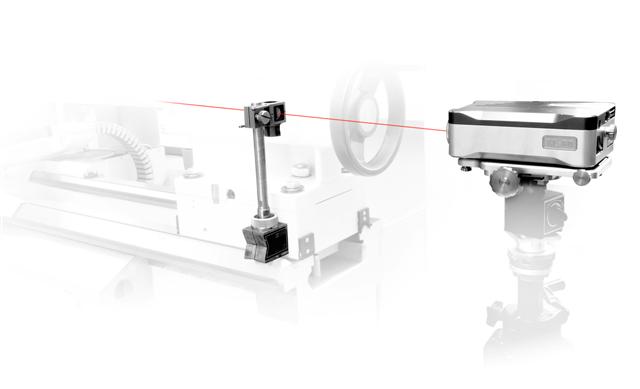

- Machine geometry measuring by laser device – the exact setting of machine axis parameters

- Variability of selection of optional turrets

- Constant cutting speed – high quality of turned surfaces

- Variety of control systems

Main advantages

- Ideal machine for a user switching from conventional to CNC controlled lathe

- Easy operation

- Manual, cycle, and automatic mode

- Software support for contour programming as well as DIN programming

- Axis positioning through servomotors

- Control system options - SIEMENS, FANUC, HEIDENHAIN

- Wide scope of executions and accessories – hydraulic clampings, chip conveyors, drilling bar holders, steady and follow rests, faceplates and chucks, hydraulic tailstock

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese